Hi. I am New to the Renault 4 and just commencing a full restoration, and new to the forum. The body is off and I want to remove the torsion bars so that I can clean up all of the suspension components and re-bush them. I have the Haynes manual, and have canvassed You tube and a couple of forums, and I just want to be clear that I understand how to handle the torsion bars. Am I correct in thinking that I can take the whole front and rear suspension units out without any "special " tools to release tension on the torsion bars. I understand that once the units are out, I can re-spline the torsion bars to different height positions if I need to. Once everything is tidied up and ready to go back, roughly how much of a 360° circle does it take to re-tension the torsion bars to secure them in position? I haven't found any diagrammatic description of the rear end of the front torsion bars that is clear to me, so I want to be sure I can get this back together again. I do appreciate the information that others have put up in the past, but it's just not clear to me how far things have to be moved, and at what point these things will bite me, to do these jobs with my present knowledge. Thanks. Ian.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1963 4L torsion bars

- Thread starter wheelnut

- Start date

Q plate

Enthusiast

- Messages

- 131

- Location

- Birmingham/ Cwmbran

Welcome Ian, I'm fairly new here to but there's a number of people on here that know these vehicles inside out & I'm sure somebody will be along to advise you correctly. I can't help with the front end as I've never stripped one but I rebuilt the rear as you intend on mine last year. Mine's a later car so slightly different but same principle. Not sure if you've searched on here but there's lots of info on the subject I also used tbe 'la4desylvie' site which is an excellent number of tutorials on the common issues including what you're doing (translate to English) following these and help from here got me sorted

JdeW

Enthusiast

- Messages

- 1,160

- Location

- Laarbeek The Netherlands

This article might be useful http://wirehead.over-blog.com/article-3605291.html

The front torsion bars are loaded and store a load of energy so beware. It needs aprox. 45° to unload the bar.

Rear torsion bars are easier to handle.

The front torsion bars are loaded and store a load of energy so beware. It needs aprox. 45° to unload the bar.

Rear torsion bars are easier to handle.

Last edited:

Amazing how easy it is when you've got good teachers. Thank you guys. The chassis is in amazing condition, so I had better do a good job of the restoration. The only rust is where moisture has sweated between the floor and the rubber mats. Three patches each about 1 ft² (300 mm) square and it'll be like new.

JdeW

Enthusiast

- Messages

- 1,160

- Location

- Laarbeek The Netherlands

Succes with your restoration I'm a little jealous that there's little rust on your R4, compared to mine.

Still busy with my rustoration that's maybe finished next year https://www.renault4.co.uk/forum/threads/r4-gtl-1985-restoration.8252/

There are many full resto projects on this forum so lots of different kinds of repairs, welding, preserving, painting etc. are available.

Just take a good look in the projects section and never hesitate to ask.

Cheers,

Joop

Still busy with my rustoration that's maybe finished next year https://www.renault4.co.uk/forum/threads/r4-gtl-1985-restoration.8252/

There are many full resto projects on this forum so lots of different kinds of repairs, welding, preserving, painting etc. are available.

Just take a good look in the projects section and never hesitate to ask.

Cheers,

Joop

Last edited:

Yes, Joop. I have seen many blogs and Youtubes of R4 chassis with severe rust, and as I bought my car sight unseen from another state, I was expecting to have to do more work on my own chassis. Naturally I'm very happy with what I have got.. My work will be in the body, where every panel has been heavily filled with putty, and where surface rust has generated between the putty fill and the panel, needing descaling and then a lot of heat shrinking and hammer and dolly work.. As a few hours on that I think.

I have almost completed installing new drivers and passenger-side floors into my chassis to remove the rusted bits. Photos to follow soon. I tried welding patches to replace only the rusted area, but the floor panel was just too thin for my welding ability, so I replaced the whole section from rail to rail.

While am waiting to set up to paint the chassis, I have started on the front suspension. First question is-all four torsion bars have a plastic sleeve over them. It is fairly knocked about and untidy. The bar inside them is nice factory finish flat black, so no corrosion has ever touched them. Is the plastic covering important? And if so, can one purchase it reasonably? Is there any aftermarket normal hardware plastic tubing available to substitute? Thanks. Ian.

While am waiting to set up to paint the chassis, I have started on the front suspension. First question is-all four torsion bars have a plastic sleeve over them. It is fairly knocked about and untidy. The bar inside them is nice factory finish flat black, so no corrosion has ever touched them. Is the plastic covering important? And if so, can one purchase it reasonably? Is there any aftermarket normal hardware plastic tubing available to substitute? Thanks. Ian.

JdeW

Enthusiast

- Messages

- 1,160

- Location

- Laarbeek The Netherlands

Yeah, know what you mean. My GTL also had a areas heavily filled with that dreadful putty. I removed it, hammered it and welded new sections in place and than lead loaded the areas to smoothen it.Yes, Joop. I have seen many blogs and Youtubes of R4 chassis with severe rust, and as I bought my car sight unseen from another state, I was expecting to have to do more work on my own chassis. Naturally I'm very happy with what I have got.. My work will be in the body, where every panel has been heavily filled with putty, and where surface rust has generated between the putty fill and the panel, needing descaling and then a lot of heat shrinking and hammer and dolly work.. As a few hours on that I think.

Just post the photo's with your progress everyone here on the forum likes to see that and keep up the good work.

angel

Enthusiast

- Messages

- 2,595

- Location

- Athens, Greece

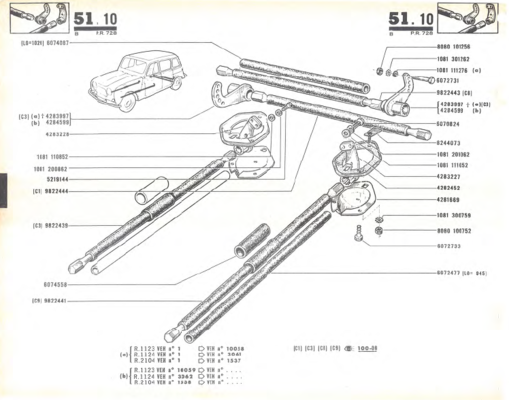

JdeW, you can see the plastic sleeves Ian is talking about on the picture, its part number 6074087 and 6072477. They were fitted on all R4s up to around 1983 model year.

Their purpose is more important than it may seem at first. Stress at a torsion bar when it is twisted is increased linearly from its centre towards its outside, where it gets highest. Under some circumstances it's possible that a stressed torsion bar will break when something hits it at its outside with relatively little force. So these sleeves are more than a protection against dirt or corrosion.

The best substitute I have found is heat shrinkable tube, the thick type with glue inside. It will shrink around three times its initial diameter, so if you get some with 35-40mm diameter you will be OK. Best way to shrink them after fitting is with a hot air gun, but you can also use a propane torch provided you move it reasonably quickly.

Their purpose is more important than it may seem at first. Stress at a torsion bar when it is twisted is increased linearly from its centre towards its outside, where it gets highest. Under some circumstances it's possible that a stressed torsion bar will break when something hits it at its outside with relatively little force. So these sleeves are more than a protection against dirt or corrosion.

The best substitute I have found is heat shrinkable tube, the thick type with glue inside. It will shrink around three times its initial diameter, so if you get some with 35-40mm diameter you will be OK. Best way to shrink them after fitting is with a hot air gun, but you can also use a propane torch provided you move it reasonably quickly.

JdeW

Enthusiast

- Messages

- 1,160

- Location

- Laarbeek The Netherlands

Yes, you're absolutely right @angel, I didn't see them when I attached the picture from PR728 although I was wearing my glasses.JdeW, you can see the plastic sleeves Ian is talking about on the picture, its part number 6074087 and 6072477. They were fitted on all R4s up to around 1983 model year.

Their purpose is more important than it may seem at first. Stress at a torsion bar when it is twisted is increased linearly from its centre towards its outside, where it gets highest. Under some circumstances it's possible that a stressed torsion bar will break when something hits it at its outside with relatively little force. So these sleeves are more than a protection against dirt or corrosion.

The best substitute I have found is heat shrinkable tube, the thick type with glue inside. It will shrink around three times its initial diameter, so if you get some with 35-40mm diameter you will be OK. Best way to shrink them after fitting is with a hot air gun, but you can also use a propane torch provided you move it reasonably quickly.

Thanks for pointing it out.

Does this mean that the later torsion bars (post 1983) were better made?

Cheers,

Joop

Thanks Angel. I imagined there must be a purpose. The closest I can find here is low pressure irrigation line, but that doesn't heat shrink so getting a thinner dia. that will be firm on the bar over the hex ends will be a challenge.

So, as I enjoy looking at others work to get some inspiration/ courage, here are some pics of my progress. Front suspension parts have arrived, so once the chassis is painted, I can start to clean/paint/assemble that. With the exception of the right side torsion bar at the lower control arm , everything came apart smoothly so I didn't need to apply my usual brute force and ignorance.

I made up floor panels, and then plug welded them in from the underneath, as that then looks the closest to standard with the seams inside. Tomorrow I will get onto getting rid of the rusty scale throughout the inside floors, and apply etch primer. Then seam sealer, then paint.

So, as I enjoy looking at others work to get some inspiration/ courage, here are some pics of my progress. Front suspension parts have arrived, so once the chassis is painted, I can start to clean/paint/assemble that. With the exception of the right side torsion bar at the lower control arm , everything came apart smoothly so I didn't need to apply my usual brute force and ignorance.

I made up floor panels, and then plug welded them in from the underneath, as that then looks the closest to standard with the seams inside. Tomorrow I will get onto getting rid of the rusty scale throughout the inside floors, and apply etch primer. Then seam sealer, then paint.

JdeW

Enthusiast

- Messages

- 1,160

- Location

- Laarbeek The Netherlands

Nice job so far and about heat shrinking tube maybe this can help in NSW https://www.auselectronicsdirect.com.au/black-30mm-heat-shrink-tubing-1.2m-lengthThanks Angel. I imagined there must be a purpose. The closest I can find here is low pressure irrigation line, but that doesn't heat shrink so getting a thinner dia. that will be firm on the bar over the hex ends will be a challenge.

harbourseal

Renault R4 Lunatic

- Messages

- 1,049

- Location

- Breda The Netherlands

I've used inner bicycle tubes to cover the torsion bars on the Sinpar 4x4 that I restored.

angel

Enthusiast

- Messages

- 2,595

- Location

- Athens, Greece

They may had decided it was a useless expense, judging by the fact that R4s were intended to be used less and less on rural roads or off road.Yes, you're absolutely right @angel, I didn't see them when I attached the picture from PR728 although I was wearing my glasses.

Thanks for pointing it out.

Does this mean that the later torsion bars (post 1983) were better made?

Cheers,

Joop

For UK folk:-

uk.rs-online.com

uk.rs-online.com

Heat Shrink Tube | Heat Shrink Sleeving | RS

Fast Delivery Heat Shrink Tube & Sleeving for Electrical Insulation, Cable Repair & Protection. Shop our huge range of Heat Shrink & accessories today.