Renaultism

Enthusiast

- Messages

- 8

- Location

- Finland

Hi!

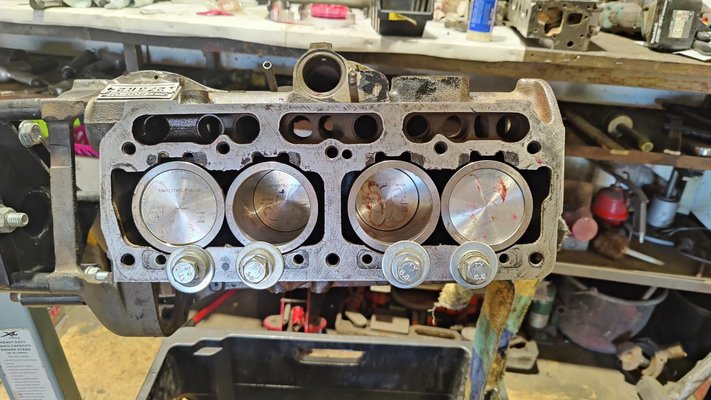

A bit advise is needed... The engine broke down, when the connecting rod came off from the crankshaft. I'm lucky because I have friends who have built engines before. BUT no French engines...

From the beginning, we had the challenge of finding out where to point those arrows. Somewhere it said to the flywheel (front) and somewhere to the cabin (rear). AI didn't help

Now it looks like that we have installed the pistons the wrong way round (and number 1 is starting from rear). Are we right that we need to disassemble the pistons? The connecting rods are probably the right way, but the pistons are wrong around (the crankshaft turns with the connecting rods alright).

Any advice is appreciated!

A bit advise is needed... The engine broke down, when the connecting rod came off from the crankshaft. I'm lucky because I have friends who have built engines before. BUT no French engines...

From the beginning, we had the challenge of finding out where to point those arrows. Somewhere it said to the flywheel (front) and somewhere to the cabin (rear). AI didn't help

Now it looks like that we have installed the pistons the wrong way round (and number 1 is starting from rear). Are we right that we need to disassemble the pistons? The connecting rods are probably the right way, but the pistons are wrong around (the crankshaft turns with the connecting rods alright).

Any advice is appreciated!