Howdy,

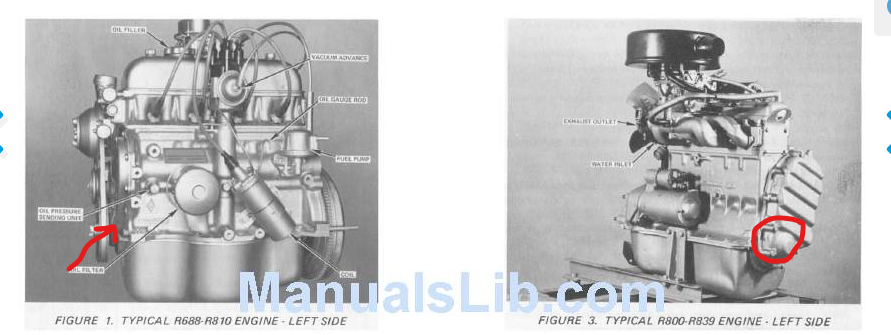

I'm across the pond in the USA and i've got a 1970-something case 1830 skidsteer powered by a 'Continental R688' which appears to be very similar to the late 60's estafette spec 688 1.1L/ 74 mm bore cleon-fonte motor. Continental imported the motors for industrial use, but aside from a different exhaust outlet location, they look pretty close to the automotive spec.

Nobody in America (well, nobody on the internet anyhow) knows anything about these engines, wants anything to do with them, and most of the tractor mechanic types who are used to big heavy cast iron stuff, say to yank it out and replace it with a motor that doesn't require metric tools to fix. Hence finding this forum and registering in hopes someone here might know more.

The motor has been good for me the last three years, the previous owner said it was rebuilt, until about 2 weeks ago when i was running it hard and suddenly noticed it smoking quite a bit. It appeared to be a loose hydraulic line dripping oil on the muffler, but after further investigation it was over a gallon low on coolant and when i filled it up, the coolant started blowing out the radiator cap. On further inspection the radiator was plugged, the cap was old and probably not holding pressure, and i removed the catch can last year because it didn't seem to be doing much of anything.

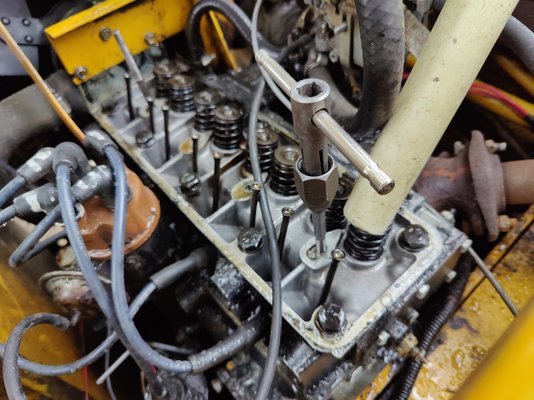

I diagnosed it to a blown head gasket, spent a lot of time learning the provenance and cross ref info for the engine and eventually tracked down an AJUSA head gasket set. Yesterday I pulled the head, cleaned everything up, replaced the gaskets, and got it all back together. Very cool little motor, smallest automotive engine i've ever worked on and over all a pretty simple and efficient design. Aside from the manifold gaskets being bonded to the head and taking almost 2 hours to scrape off... everything went really well and it was back together and running in time for me to clean up before dinner.

Now here are my questions:

1) When i first pulled the head, i noticed the two middle cylinder liners were a little 'wobbly'... I've never worked with wet liners before, but when i've heard of other engines using them, they are a heavy press fit. These appear to be a slip fit, is that correct? To make matters worse, i bumped the starter, not thinking about this, to clean the coolant out of the cylinders and further disloged the cylinder, it never came up, and the coolant still sitting in the block didn't end up in the oil, but my question is regarding the sealing at the bottom of the bore.

Since the engine was recently rebuilt, the oring should still be fairly pliable down there. I am hoping it will hold, my plan is to change and check the oil after the first couple good heat cycles, maybe even re-torque the head? Does this sound reasonable or is there something else i should do?

My 'last ditch' idea would be to fill the block only with coolant with leak-stop and let the engine get hot to cook it in there. If the engine has to come out, i don't think i will be putting it back in since it is not quite up to the task of running a skidsteer, and parts over here are hard to come by.

2) When i took the head off, the break-away (loosening torque) on the head bolts was low, very low, like less than 15 lbs on the bolts. Would this be normal for an engine that's overheated? Or would this be a sign of an incorrectly done rebuild. The engine was professionally rebuilt less than 60 hours ago, but once again since this is such an odd engine for USA, i'm worried that things might not have been done right.

Thanks for reading and any responses, sorry for the long winded post. If i get a chance later i'll add some pics for fun. I'm not sure if the skidsteer thing is common knowledge in Europe or if this is a novelty for you guys to see. Certainly fun for me to work on something thats so unusual for the type of things we usually see here.

I'm across the pond in the USA and i've got a 1970-something case 1830 skidsteer powered by a 'Continental R688' which appears to be very similar to the late 60's estafette spec 688 1.1L/ 74 mm bore cleon-fonte motor. Continental imported the motors for industrial use, but aside from a different exhaust outlet location, they look pretty close to the automotive spec.

Nobody in America (well, nobody on the internet anyhow) knows anything about these engines, wants anything to do with them, and most of the tractor mechanic types who are used to big heavy cast iron stuff, say to yank it out and replace it with a motor that doesn't require metric tools to fix. Hence finding this forum and registering in hopes someone here might know more.

The motor has been good for me the last three years, the previous owner said it was rebuilt, until about 2 weeks ago when i was running it hard and suddenly noticed it smoking quite a bit. It appeared to be a loose hydraulic line dripping oil on the muffler, but after further investigation it was over a gallon low on coolant and when i filled it up, the coolant started blowing out the radiator cap. On further inspection the radiator was plugged, the cap was old and probably not holding pressure, and i removed the catch can last year because it didn't seem to be doing much of anything.

I diagnosed it to a blown head gasket, spent a lot of time learning the provenance and cross ref info for the engine and eventually tracked down an AJUSA head gasket set. Yesterday I pulled the head, cleaned everything up, replaced the gaskets, and got it all back together. Very cool little motor, smallest automotive engine i've ever worked on and over all a pretty simple and efficient design. Aside from the manifold gaskets being bonded to the head and taking almost 2 hours to scrape off... everything went really well and it was back together and running in time for me to clean up before dinner.

Now here are my questions:

1) When i first pulled the head, i noticed the two middle cylinder liners were a little 'wobbly'... I've never worked with wet liners before, but when i've heard of other engines using them, they are a heavy press fit. These appear to be a slip fit, is that correct? To make matters worse, i bumped the starter, not thinking about this, to clean the coolant out of the cylinders and further disloged the cylinder, it never came up, and the coolant still sitting in the block didn't end up in the oil, but my question is regarding the sealing at the bottom of the bore.

Since the engine was recently rebuilt, the oring should still be fairly pliable down there. I am hoping it will hold, my plan is to change and check the oil after the first couple good heat cycles, maybe even re-torque the head? Does this sound reasonable or is there something else i should do?

My 'last ditch' idea would be to fill the block only with coolant with leak-stop and let the engine get hot to cook it in there. If the engine has to come out, i don't think i will be putting it back in since it is not quite up to the task of running a skidsteer, and parts over here are hard to come by.

2) When i took the head off, the break-away (loosening torque) on the head bolts was low, very low, like less than 15 lbs on the bolts. Would this be normal for an engine that's overheated? Or would this be a sign of an incorrectly done rebuild. The engine was professionally rebuilt less than 60 hours ago, but once again since this is such an odd engine for USA, i'm worried that things might not have been done right.

Thanks for reading and any responses, sorry for the long winded post. If i get a chance later i'll add some pics for fun. I'm not sure if the skidsteer thing is common knowledge in Europe or if this is a novelty for you guys to see. Certainly fun for me to work on something thats so unusual for the type of things we usually see here.