AdamWilkes

Enthusiast

- Messages

- 407

- Location

- Poole

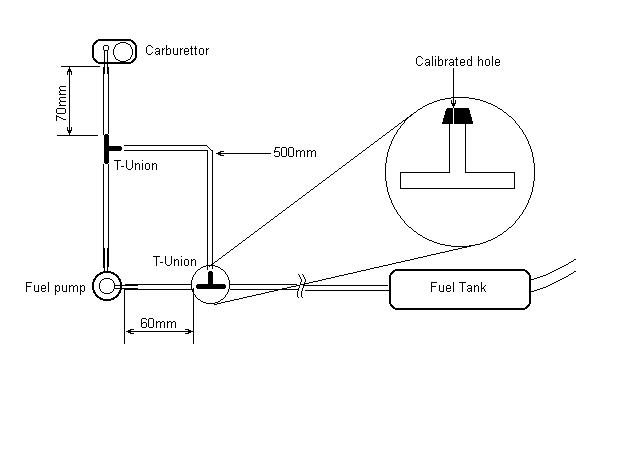

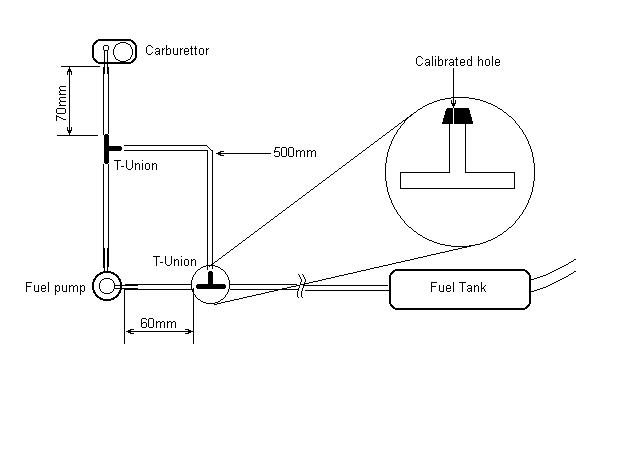

In a thread to do with ignition problems, I found a petrol-pipe modification (also suggested by Renault, I think). It helps to cool the petrol in the engine-bay a touch (reducing any problems experienced with vapour-lock/petrol evaporation when parked-up after a hot run), and eliminates residual pipe-pressure when the engine is not running. The modification is two T-joints (I used brass 6mm types) and the 6mm hose between them, as below:

The calibrated hole size was not known. I soldered over the right-hand brass T-joint exit pipe (the T-joint nearer the carb), and then drilled though the solder. I tried a 1.5mm diameter, but the pump could not pump petrol after it had been stood overnight. Petrol pumped (visible through my clear petrol-filter between fuel pump and carb-end T-junction) seems 'splashy', and may be full of bubbles, which I guess keep on circulating around the new pipework. Bleeding the pipework may help, but it would need doing every time one had a dry pipe; maybe re-routing pipes to eliminate air-traps would help (bubbles would be vented into the carb), but that's not all that easy.

The pump can't make the same pressure as before, as it's outlet pipe is open (through the small calibrated hole) back through to the petrol tank. The pressure needed is that to raise the petrol from the tank up to the carb, and is a lot less than a good pump can produce, so the calibrated hole needs to be small enough to still let the pump do it's work without bleeding the pressure straight back to the tank.

I tried a 1mm hole, and that seems to work, though I suspect a slightly smaller hole still would be better.

Whether this tiny hole size is actually any good for cooling circulating petrol enough, I am unsure, but it certainly de-pressurises the pipes when the engine is off.

The calibrated hole size was not known. I soldered over the right-hand brass T-joint exit pipe (the T-joint nearer the carb), and then drilled though the solder. I tried a 1.5mm diameter, but the pump could not pump petrol after it had been stood overnight. Petrol pumped (visible through my clear petrol-filter between fuel pump and carb-end T-junction) seems 'splashy', and may be full of bubbles, which I guess keep on circulating around the new pipework. Bleeding the pipework may help, but it would need doing every time one had a dry pipe; maybe re-routing pipes to eliminate air-traps would help (bubbles would be vented into the carb), but that's not all that easy.

The pump can't make the same pressure as before, as it's outlet pipe is open (through the small calibrated hole) back through to the petrol tank. The pressure needed is that to raise the petrol from the tank up to the carb, and is a lot less than a good pump can produce, so the calibrated hole needs to be small enough to still let the pump do it's work without bleeding the pressure straight back to the tank.

I tried a 1mm hole, and that seems to work, though I suspect a slightly smaller hole still would be better.

Whether this tiny hole size is actually any good for cooling circulating petrol enough, I am unsure, but it certainly de-pressurises the pipes when the engine is off.