petak

Enthusiast

- Messages

- 1,894

- Location

- Vodice, Croatia

It was not easy (mostly nerve taking job) but this is all mechanical part that can be put back together.

The biggest question is.....How good grooves are?

Because if there is to much air/space between rings and grooves than your driveshaft will make that recognizable TOK-TOK sound when accelerating and cornering.

Will show you some "dents" that were on this drive shaft in grooves

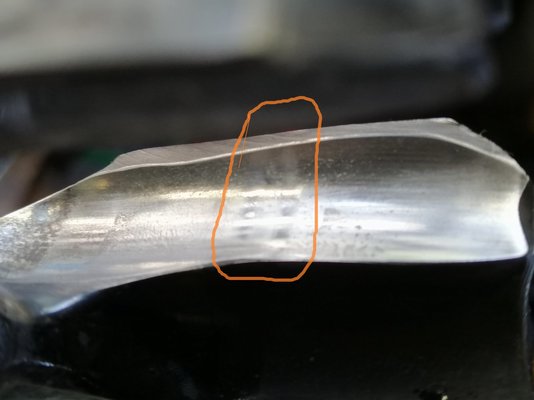

One of the grooves. You can notice two vertical smooth lines in the middle of groove.

Here is same picture where i have pointed out that vertical smooth lines.

Rolling rings made them thru time of driveshaft use

When driveshafts are "repaired" this grooves are welded and grinned so that surface is again flat.

I have just polished them slightly

Now it is big question have i done good thing and repair driveshaft. Welding part is missing in my process so airiness between rolling ring and grooves is bigger than before.

Or i have made bad thing and driveshaft need professional repair.

Test ride soon (i hope)

The biggest question is.....How good grooves are?

Because if there is to much air/space between rings and grooves than your driveshaft will make that recognizable TOK-TOK sound when accelerating and cornering.

Will show you some "dents" that were on this drive shaft in grooves

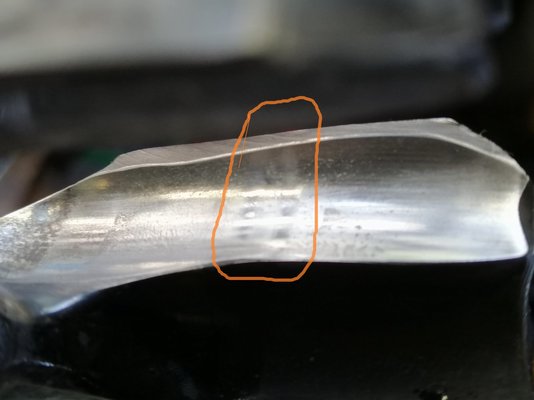

One of the grooves. You can notice two vertical smooth lines in the middle of groove.

Here is same picture where i have pointed out that vertical smooth lines.

Rolling rings made them thru time of driveshaft use

When driveshafts are "repaired" this grooves are welded and grinned so that surface is again flat.

I have just polished them slightly

Now it is big question have i done good thing and repair driveshaft. Welding part is missing in my process so airiness between rolling ring and grooves is bigger than before.

Or i have made bad thing and driveshaft need professional repair.

Test ride soon (i hope)