JdeW

Enthusiast

- Messages

- 1,094

- Location

- Laarbeek The Netherlands

Thanks, the things you can achieve with a little patience, manual labor, tools, a vice, an anvil and a MIG welderGreat job with sheet metal!

Thanks, the things you can achieve with a little patience, manual labor, tools, a vice, an anvil and a MIG welderGreat job with sheet metal!

When you lead loading make sure to neutralise with bicarbonate of soda when repair is over as it will rust like hell. The acid is highly corrosive,great work!The body has been hoisted into the ridge of the shed by the use of an electric winch.

Time to clean the garage first and for the couple of following weeks it's time to clean the underside of the body, finishing off the welds on several places, performing some lead loading and many other things we normally don't see or overlook.

View attachment 31013

Thanks for the tip, I am aware of the corrosive properties of the acid. Work will commence next spring due to winter.When you lead loading make sure to neutralise with bicarbonate of soda when repair is over as it will rust like hell. The acid is highly corrosive,great work!

Thanks Hrvoje, I'm glad to be back with the project, but the house had and still has priority over the R4.As start i must say that i am really very happy that you are back to this project.

I have learned a lot from your posts

Way you are dealing with panel rust and panel welding is impressive.

![20221209_114954[1].jpg 20221209_114954[1].jpg](https://www.renault4.co.uk/forum/data/attachments/29/29809-192d3e07ced347abc5bd649fea64e382.jpg?hash=GS0-B87TR6)

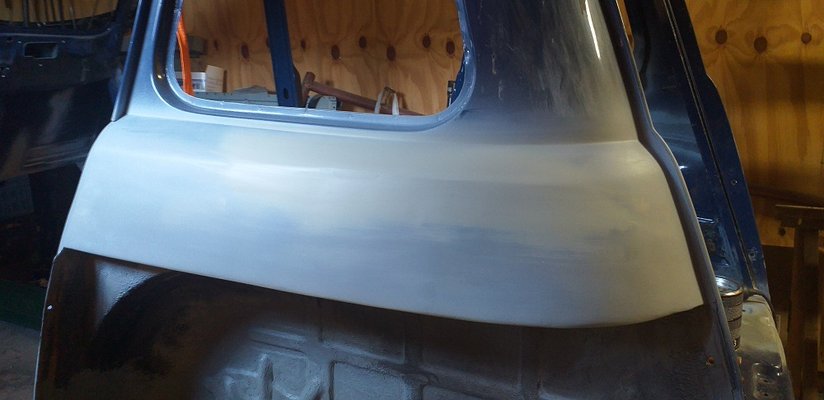

I started using lead loading 50 years ago, and you have done a brilliant job ! Well done !Hello people, it's been a while, actually it's been more than quite a while, but I'm back with what is for me the most challenging job, preparation before the body paintjob.

As I wrote before I'll use lead loading as base and the goal is to use the least amount of putty as possible. The challenge lies in the fact that I'm a true mechanic and totally not a sculpter or an art artist but I'll give it a try.

The attached pictures show only one side but it applies to the other side as well.

Starting with tinning the body using the solder flux.

Applying the lead and spreading it out.

More lead and starting using a grater.

And after a while a nice crude shape is formed.

The fine art is done with metal putty and loads of sanding, looking, feeling, sanding, looking, feeling etc. etc.

Finally after several very thing layers of primer, spray putty, primer etc. and by the use of 1200 grit waterproof sanding paper there is a result.

More preparation work has been done at the A and B pillar attacking the areas where the flash rust resides.

It was especially bad at the A pillar, when I dismantled the car I already saw it, as if there was hardly any paint.

More preparation has been done using sealant in the rear wheel arches, the engine bulkhead and sanding the inner bulkhead.

That's it for now, cheers

Thanks @Homegrown, I like reading your project as well and yes I'd to improvise on some occasions as chassis parts are either way to expensive or not obtainable, so why not recreate some by yourself.Nice you are back again

Read your thread again from start to "finish" during my night shift at work. Great work you are doing whatever you sort out.

.

.

Thanks Malcolm, Indeed I've installed a water and oil seperator/filter after the compressor and additional there's an extra filter at the spray gun.This is a really nicely done project. Have you got a water drier in the feed to the paint gun? - https://www.mig-welding.co.uk/air-system.htm Might be something everybody else knows about but for me it took 20 years to figure that bit out so worth mentioning before you do the top coat.