mojobaby

Enthusiast

- Messages

- 1,310

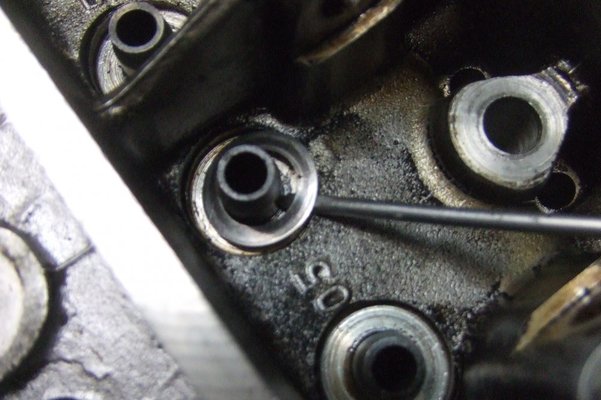

This week, I started work on the cylinder head. I found it quite difficult to press down the valve springs with one hand and remove the collets (keepers) with the other, so I built a simple jig to help me. I expected the collets to fall out but they were firmly held in place by old thick oil. With the jig, I could use two hands to remove them.

Once the springs were removed, I also expected the valves to slide out through the guides, but they got stuck. The tops of the valves had mushroomed from contact with the rockers (incorrect gap settings.) After some advice from Angel, I polished the tops with 400 grit paper for about 15 minutes and that allowed them to slide through the guides.

Here are some photos of the jig, they might help someone. Took me 30 minutes to make and cost nothing.

Once the springs were removed, I also expected the valves to slide out through the guides, but they got stuck. The tops of the valves had mushroomed from contact with the rockers (incorrect gap settings.) After some advice from Angel, I polished the tops with 400 grit paper for about 15 minutes and that allowed them to slide through the guides.

Here are some photos of the jig, they might help someone. Took me 30 minutes to make and cost nothing.