JdeW

Enthusiast

- Messages

- 1,094

- Location

- Laarbeek The Netherlands

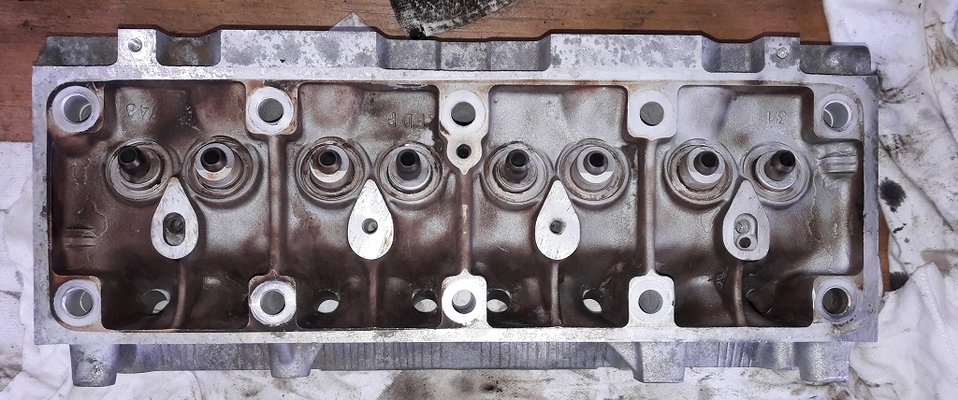

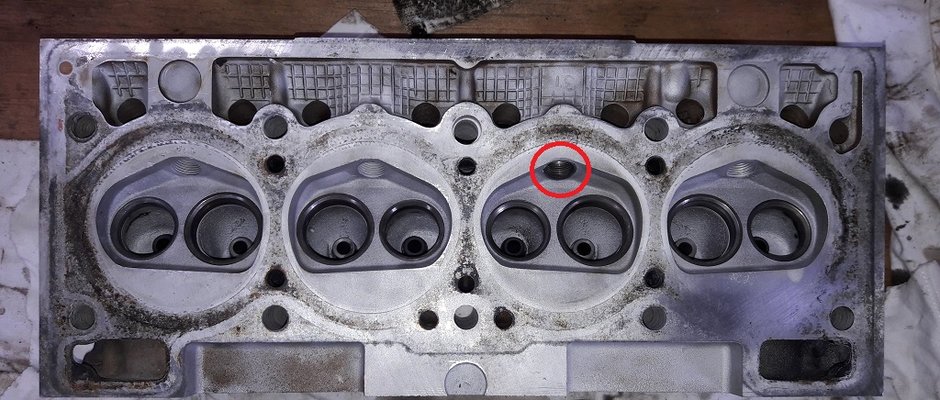

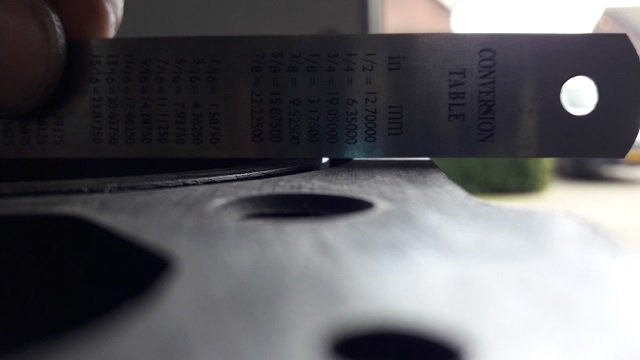

Again a few pictures about dismantling the engine.

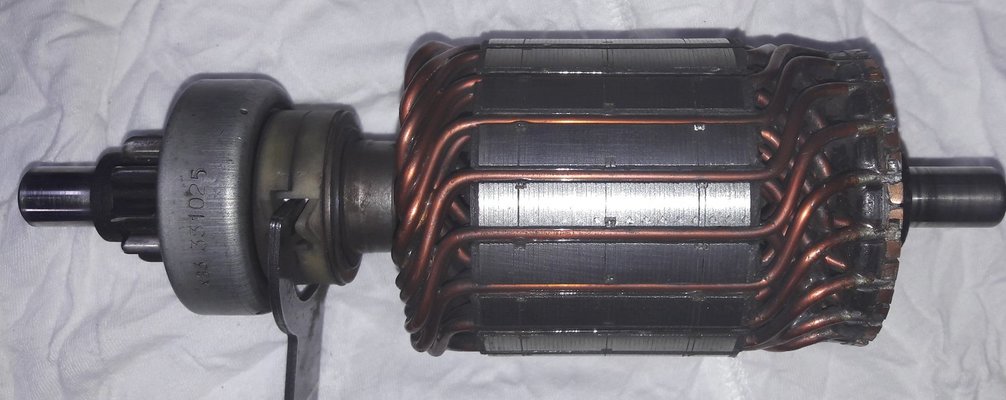

The oil pump is later to be further disassembled and cleaned.

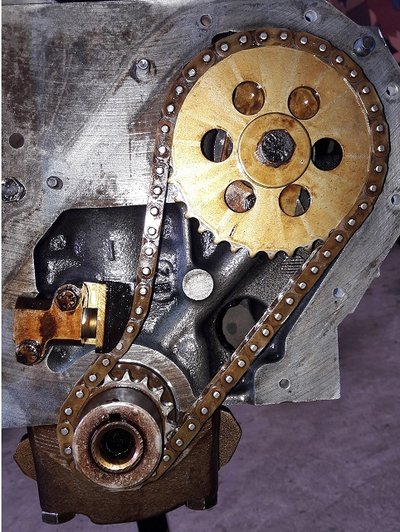

A peek behind camshaft sprocket. Chain and sprockets look good, usually go with 500,000 km (312500 mi) before having to be replaced.

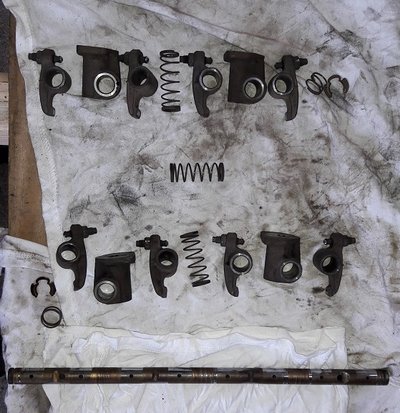

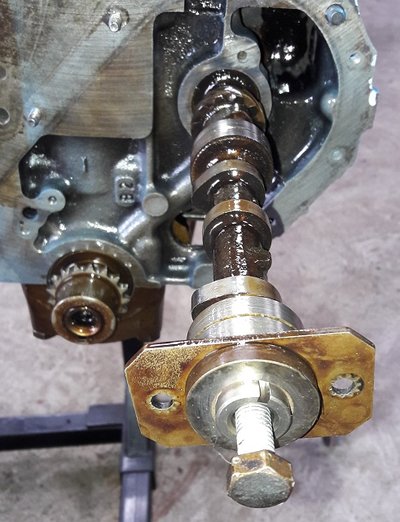

Removing the camshaft, first remove the distributor shaft (which is very easy on Cleon type engines)

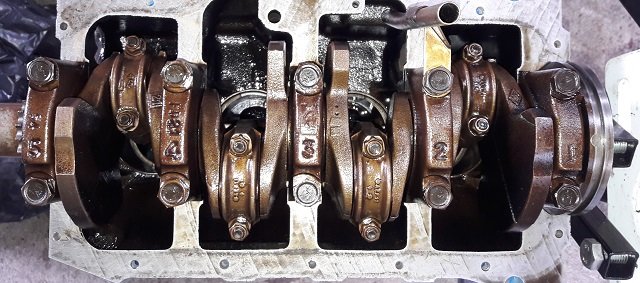

A peek on the crankshaft.

Connecting rod bearings on piston No. 1.

Extracting the piston with its liner.

Keep everything on sequence and to each other.

17 bhp left

And finally the connecting rod bearings on piston No. 4.

A peek at the connecting rod faces on the crankshaft and decided it will get a grinding and polishing turn.

The oil pump is later to be further disassembled and cleaned.

A peek behind camshaft sprocket. Chain and sprockets look good, usually go with 500,000 km (312500 mi) before having to be replaced.

Removing the camshaft, first remove the distributor shaft (which is very easy on Cleon type engines)

A peek on the crankshaft.

Connecting rod bearings on piston No. 1.

Extracting the piston with its liner.

Keep everything on sequence and to each other.

17 bhp left

And finally the connecting rod bearings on piston No. 4.

A peek at the connecting rod faces on the crankshaft and decided it will get a grinding and polishing turn.

Last edited:

.

.

and the youngest son a megatronica student

and the youngest son a megatronica student