You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

R4 TL restauration

- Thread starter Jurjenz

- Start date

Jurjenz

Enthusiast

- Messages

- 468

- Location

- Groningen, Netherlands

Hi Guys!

Sunday, well - it was a bit of a lazy day.. I organised my toolbox and I cleaned the workshop

I also did some smal thingies:

-sandblasting & painting the supportbracket for the carburator

-cleaning the front innerwing. Those were swedisch, so i had a 1 cm thick protection layer on it. Took me 2 hours to clean! (one more to go...)

-some 'pre-assembling' on the cilinderhead

This week is my last week of the summerholiday, dammit...

Sunday, well - it was a bit of a lazy day.. I organised my toolbox and I cleaned the workshop

I also did some smal thingies:

-sandblasting & painting the supportbracket for the carburator

-cleaning the front innerwing. Those were swedisch, so i had a 1 cm thick protection layer on it. Took me 2 hours to clean! (one more to go...)

-some 'pre-assembling' on the cilinderhead

This week is my last week of the summerholiday, dammit...

Last edited:

Jurjenz

Enthusiast

- Messages

- 468

- Location

- Groningen, Netherlands

Haha, so true Jonathan!

Today I have been working on the steering mechanism. I find the cause why rotating was so hard.

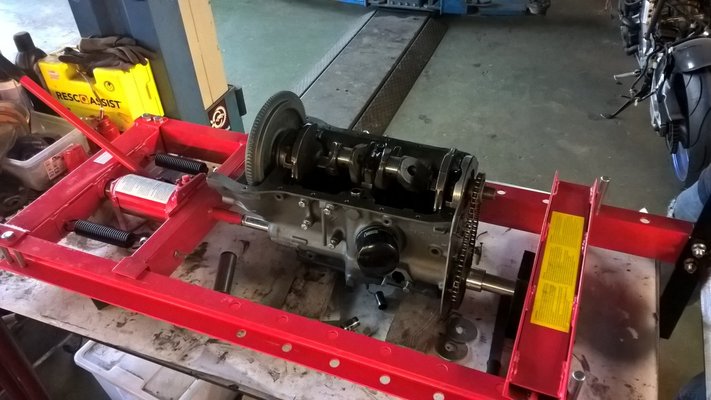

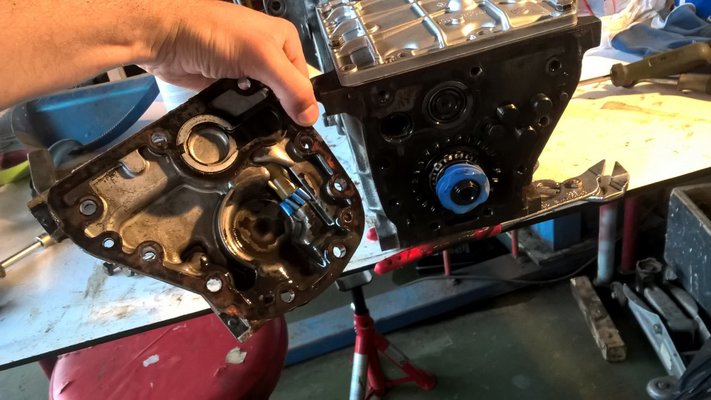

This afternoon I went to another engineshop. What a difference! I was helped very friendly and the mechanic also checked the pistons & rings. Worn out to the bone.. He will polish the bearing areas (don't know correct word) on the crankshaft (it has some tiny scratches) and he will measure them so I can order the right bearings.

Funny, he was restoring a Mustung '67 and the owner of the company a 4CV. We had a pleasant talk!

Question:

I placed the front shock absorbers, is it correct I can't bolt them on the top due to the unloaded chassis? I'm not sure if the height is correct now.. Any advice? I didn't measure the distance from ground to floor when only the chassis was left... Lesson learned..

cheers!

Today I have been working on the steering mechanism. I find the cause why rotating was so hard.

This afternoon I went to another engineshop. What a difference! I was helped very friendly and the mechanic also checked the pistons & rings. Worn out to the bone.. He will polish the bearing areas (don't know correct word) on the crankshaft (it has some tiny scratches) and he will measure them so I can order the right bearings.

Funny, he was restoring a Mustung '67 and the owner of the company a 4CV. We had a pleasant talk!

Question:

I placed the front shock absorbers, is it correct I can't bolt them on the top due to the unloaded chassis? I'm not sure if the height is correct now.. Any advice? I didn't measure the distance from ground to floor when only the chassis was left... Lesson learned..

cheers!

Last edited:

mr-reno-139

AKA Paul Cunningham

- Messages

- 2,268

- Location

- lancing west sussex england

Harder to fit shocks as ther is no weight to stop the body lifting as you put a jack under lower arm

Assuming torsion bars refitted as original some helpers sitting on front of chassis wiil let you get top.nut in place

Don't worry about height until whole car all back together

Looking at steering bearing is the pinion shaft ok ?

Assuming torsion bars refitted as original some helpers sitting on front of chassis wiil let you get top.nut in place

Don't worry about height until whole car all back together

Looking at steering bearing is the pinion shaft ok ?

Jurjenz

Enthusiast

- Messages

- 468

- Location

- Groningen, Netherlands

mr-reno-139

AKA Paul Cunningham

- Messages

- 2,268

- Location

- lancing west sussex england

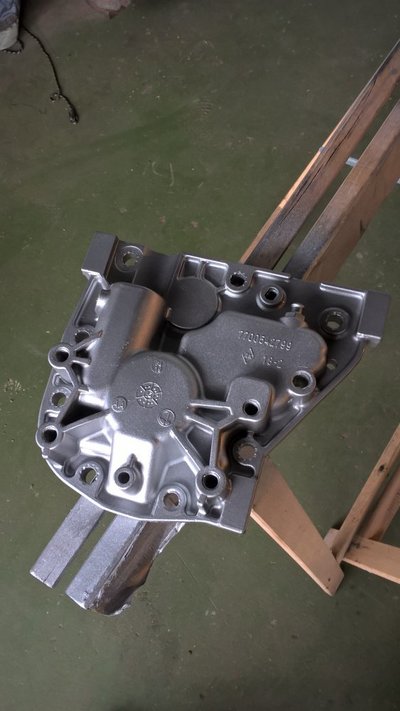

Think it was discussed recently about how far to press sprocket on as there needs to be a small amount of end float

Hopefully your supplier will swap piston for correct type

Thought the engine code would identify them

I've got 3 with the 14 mm pin same as dauphine

Hopefully your supplier will swap piston for correct type

Thought the engine code would identify them

I've got 3 with the 14 mm pin same as dauphine

Jurjenz

Enthusiast

- Messages

- 468

- Location

- Groningen, Netherlands

mojobaby

Enthusiast

- Messages

- 1,311

Hello Jurjenz your radiator looks like new again, but have you had it pressure tested or perhaps filled it with water to check for leaks? I spent a few hours cleaning mine and only after I fitted it did I discover that it leaked badly . So I ended up buying a new one.

. So I ended up buying a new one.

The blockage in the little tube on your manifold is oil from the fumes from your rocker cover. If it stayed blocked, then the fumes would be sucked into the top of your carburetor and cause an oily mess inside. There should be a restrictor pipe in the rubber hose that leads to that little pipe. The restrictor has a 1,30mm hole in it to let the fumes through.

My engine actually ran better when the pipe was blocked, so I made my own restrictor with a 1,00mm hole in it and it now runs better.

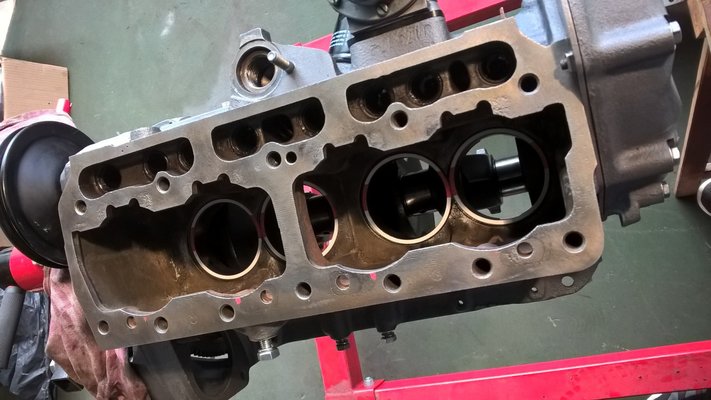

Beautiful set of pistons!!

. So I ended up buying a new one.

. So I ended up buying a new one.The blockage in the little tube on your manifold is oil from the fumes from your rocker cover. If it stayed blocked, then the fumes would be sucked into the top of your carburetor and cause an oily mess inside. There should be a restrictor pipe in the rubber hose that leads to that little pipe. The restrictor has a 1,30mm hole in it to let the fumes through.

My engine actually ran better when the pipe was blocked, so I made my own restrictor with a 1,00mm hole in it and it now runs better.

Beautiful set of pistons!!

Jurjenz

Enthusiast

- Messages

- 468

- Location

- Groningen, Netherlands